Kinderfeets Kinderboard (Natural) Kinderfeets

$ 199,00 $ 79,60

A fun multi purpose wooden toy. Originally used in Waldorf early childhood classrooms. It was created to help children develop a sense of balance, stimulate their vestibular system, and gain a deep sense of awareness of their body and body parts.

Due to the bulky nature of this toy, this is available for pick up in store option only.

We Do Not Ship this item

Manufacturers Recommended Age: 18 Months +

Max Weight: 220 Kg

This is the natural version, some of the images show the white wash kinderfeets kinderboard, these are included to inspire you to use the board in different ways. Please refer to the image of the kinderboard on its own for the best colour representation.

Watch your child’s imagination take over once their Kinderboard arrives. It becomes a seesaw, a balance board, a slide, a step stool, a boat, a resting place, a doll bed, a puppet stage, a tunnel and many more opportunities for them to explore. The possibilities are endless—and truly up to them!

The making of a Kinderboard

Kinderboards look deceptively simple. Developed for use in Waldorf early childhood classrooms they’re a simple but rather clever concept for developing a child’s balance, stimulating their vestibular system and helping them gain a deeper awareness of their body and body parts. However, as is often the case with many of the world’s most enduring toys things are never quite what they seem.

A Kinderboard’s hidden cost and complexity begins with the raw material used in its manufacture. Each board is made using Beech plywood; a heavier, denser timber than other cheaper options. This ensures it’s both strong and durable and thus will endure plenty of energetic play. The timber used is also FSC certified. This means it’s often more expensive than untraceable non-sustainability harvested alternatives.

Before a board can be shaped its plywood must first be manufactured. This process involves kiln drying the raw timber until its moisture content falls below 2%. Thin timber veneer sheets are then cut from each log. These are carefully layered and glued by hand to form a plywood panel. Rectangular shapes cut from each panel then begin the journey that results in a finished Kinderboard.

Creating their elegant shape is the first step. Super-heated steam is used to soften the raw plank at a temperature of more than 130°C. The plank is then carefully bent using a custom built shaping form. The form holds the plank under tension until the softened wood cools and hardens into its final curve. It almost an hour to bend and set each board. This process involves expensive industrial steam presses that make only one board at a time. This obviously limits the number of boards you can make in a day. Furthermore, not all planks survive the shaping process and must be discarded.

Raw planks that made through the shaping process are then sanded and shaped by hand to ensure a smooth and elegant finish. This includes the addition of each board’s deceptively simple corner curves. Adding these finishing touches is a surprisingly time-consuming task.

The completed Kinderboard is then stained and lacquered. This involves up to four coats per board. Each coat is applied by hand and then hand sanded before the next is applied. Kinderfeets uses ecologically friendly stains and lacquers. These are more expensive than solvent-based alternatives.

Fast Shipping and Professional Packing

Because of our long-standing relationship with UPS FedEx DHL and other major international carriers, we are able to provide various shipping options. Our warehouse staff is highly skilled and will pack your items according to our precise and exact specifications. Your items are carefully inspected and secured properly prior to shipping. We deliver to thousands of customers every day from all over the world. This demonstrates our dedication to become the biggest online retailer in the world. The distribution centers and warehouses distribution are located in Europe, as well as the USA.

Note: Orders with more than one item are assigned a processing period depending on the item.

Prior to shipping, we check the item thoroughly before sending the items. The majority of orders are delivered within 48 hours. The expected delivery time will be between 3-7 days.

Returns

Stock is dynamic. It's not entirely managed by us, as we have multiple entities, including the factory and the storage. The actual stock levels can fluctuate at any time. It is possible that your order is out of stock once the order is placed.

Our policy lasts for 30 days. Unfortunately, if the 30 days have elapsed after you bought your item, we cannot provide a refund or exchange.

Your item must be in the original packaging and in good condition. It must also not be used. The item must be returned in its original packaging.

Related products

Kids Accessories Eating & Drinking

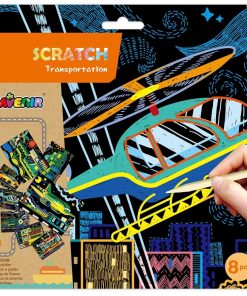

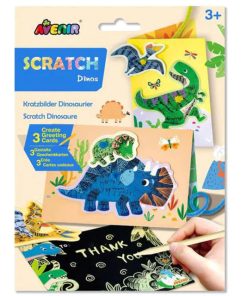

Toys Art, Craft & Stickers

Toys Art, Craft & Stickers

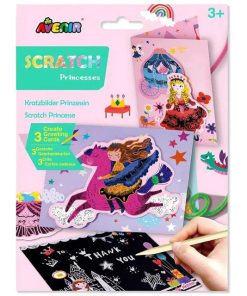

Avenir Scratch Greeting Card Set (Princess) Avenir Art & Craft

Toys Role Play

Toys Art, Craft & Stickers

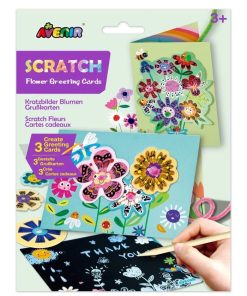

Avenir Scratch Greeting Card Set (Flowers) Avenir Art & Craft

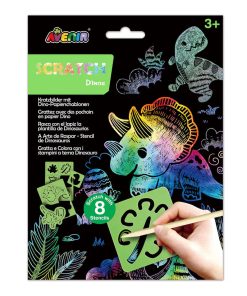

Toys Art, Craft & Stickers

Toys Role Play

Toys Role Play

Toys Dolls

Toys Puzzles & Games

Toys Animals

Kids Accessories Eating & Drinking

Toys Art, Craft & Stickers

Toys Role Play

Toys Animals

Toys Role Play

Toys Learning, Music & Science

Kids Accessories Eating & Drinking

Kids Accessories Eating & Drinking

Toys Early Explorers

Toys Dolls

Toys Art, Craft & Stickers

Toys Animals

Toys Art, Craft & Stickers

Kids Accessories Eating & Drinking

Toys Dolls

Toys Art, Craft & Stickers

Avenir Nail Stickers & Tattoos (Christmas) Avenir Art & Craft

Toys Wheels, Wings & Trains